Cut Costs, Not Corners: The Secrets to Long-Lasting Equipment

For businesses that rely on heavy machinery, power tools, or industrial systems, equipment longevity directly impacts profitability. Every repair, replacement, or unexpected breakdown can disrupt workflow and strain budgets. The challenge is finding ways to control costs without compromising on quality or performance. Extending equipment life isn’t about cutting corners; it’s about smarter management, preventive care, and understanding how to maintain efficiency. With the right approach, organizations can reduce expenses, increase reliability, and maintain productivity without sacrificing safety or results.

Investing in Quality From the Start

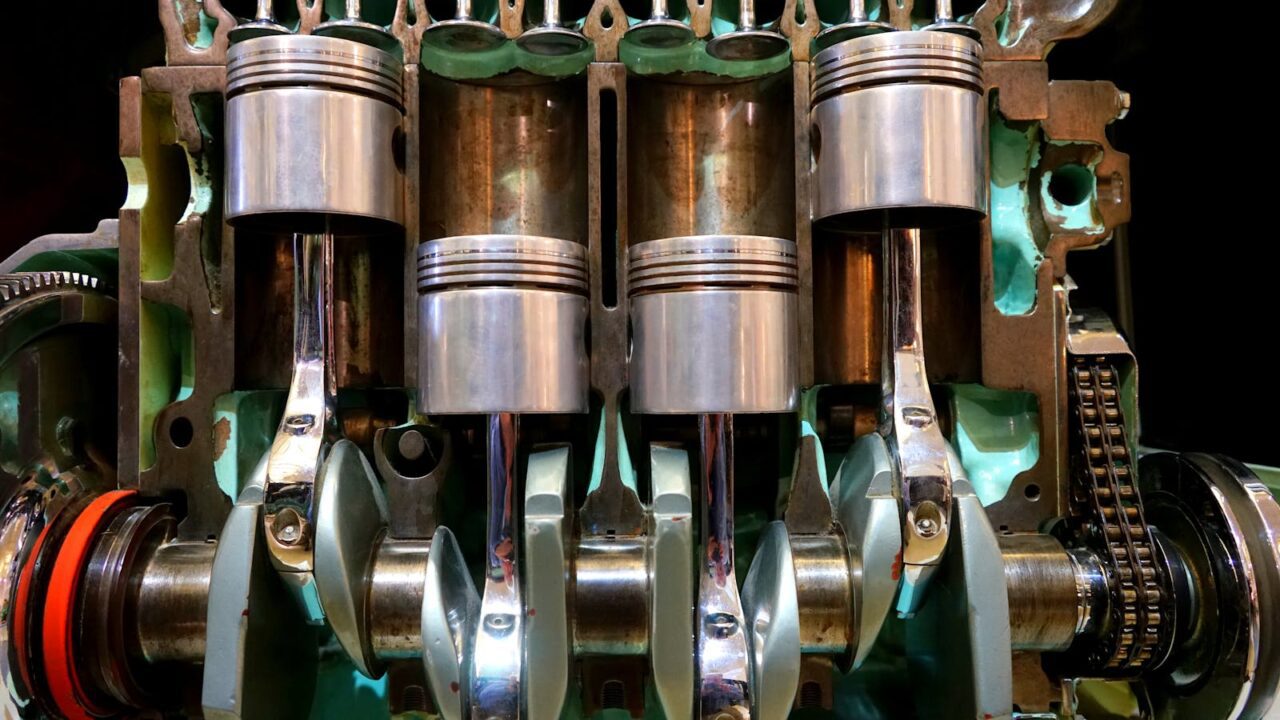

Durability begins with the right purchase decisions. High-quality equipment may cost more upfront, but it often proves more economical in the long run due to lower repair frequency and better performance. Before making any investment, evaluate the manufacturer’s reputation, warranty terms, and availability of replacement parts.

Machines built with precision components and durable materials withstand daily wear far better than cheaper alternatives. One of the most effective cost-saving strategies is to look into Lavina equipment parts and similar high-grade products designed specifically for long-term use. Choosing brands that provide accessible support and genuine components prevents compatibility issues that can shorten equipment life.

This approach doesn’t just protect performance, it ensures that every maintenance effort yields lasting results. By focusing on reliability and verified sourcing, companies avoid the hidden costs associated with frequent breakdowns and inconsistent quality.

Building a Preventive Maintenance Plan

A well-structured maintenance plan is crucial for extending the life of any machine. Instead of waiting for parts to fail, proactive upkeep identifies potential issues early, saving both time and money. Regular inspections, lubrication schedules, and cleaning routines should be standard practice. Keeping detailed maintenance logs helps track performance patterns and anticipate component replacements before they cause downtime.

Preventive care reduces stress on moving parts and keeps systems running efficiently. Operators who follow consistent schedules experience fewer emergencies and lower long-term repair costs. Maintenance plans should include seasonal adjustments, as changes in temperature and humidity can affect performance. Prevention costs far less than emergency repairs, and it extends the lifespan of expensive equipment significantly.

Training Operators for Proper Use

Even the best-maintained machinery will fail prematurely if it’s used incorrectly. Operator error remains one of the most common causes of damage. Comprehensive training programs ensure that employees understand how to use equipment safely and efficiently. This includes correct startup and shutdown procedures, proper load handling, and awareness of operating limits.

Supervisors should reinforce best practices through periodic reviews and refresher sessions. Encouraging accountability among operators builds a culture of responsibility where everyone takes ownership of the equipment they use. Well-trained teams minimize accidents and contribute to better performance, reduced downtime, and fewer costly mistakes.

Keeping Equipment Clean and Calibrated

Dirt, dust, and debris are silent enemies of mechanical systems. Accumulated grime can interfere with moving parts, cause overheating, and shorten the lifespan of components. Regular cleaning removes contaminants that lead to wear and corrosion. This step is crucial in industries like construction, manufacturing, and agriculture, where machinery faces harsh environments daily.

Calibration plays a major role in maintaining efficiency. Vibrations and use can throw settings out of alignment, leading to inaccurate output or uneven wear. Routine calibration ensures precision and prevents unnecessary strain on parts. Equipment that operates within its intended tolerances runs smoother, lasts longer, and produces consistent results. Simple cleaning and calibration practices often make the difference between years of dependable service and premature failure.

Storing Machinery Correctly

Improper storage can degrade equipment faster than heavy use. Exposure to moisture, dust, or extreme temperatures causes rust, corrosion, and mechanical failure. Every tool or machine should have a designated storage area that’s clean, dry, and organized. Covering equipment when not in use adds an extra layer of protection against environmental damage.

For larger machinery, periodic startup during storage keeps fluids circulating and prevents internal parts from seizing. Batteries should be disconnected or maintained to avoid drainage. Taking the time to store equipment properly ensures that it remains in good condition between uses, reducing the likelihood of costly surprises when it’s needed again.

Monitoring Performance Through Data

Technology now makes it easier than ever to track equipment performance and detect early signs of wear. Many modern machines come equipped with sensors and diagnostic systems that monitor usage, temperature, and efficiency. Collecting and analyzing this data helps identify irregularities that may indicate developing problems.

Implementing asset management software centralizes this information, allowing managers to make informed decisions about repairs, replacements, and upgrades. Predictive maintenance, powered by data, can pinpoint exactly when components need attention. This precision saves money, prevents downtime, and optimizes resource allocation. Data-driven maintenance transforms guesswork into strategy, giving companies a competitive advantage in both performance and cost control.

Extending equipment life requires discipline, attention to detail, and a commitment to quality. Companies that prioritize proper maintenance, use trusted parts, and train employees thoroughly enjoy smoother operations and stronger profits. When businesses focus on long-term value rather than quick savings, they not only preserve their equipment, but they also build lasting efficiency that keeps them competitive for years to come.

Leave a Reply

You must be logged in to post a comment.